Wedge wire screens can be manufactured in two different variants. We distinguish them as either Welded Wedge Wire screens or Looped Wedge Wire screens.

The distinction is based on how the screens are constructed and manufactured.

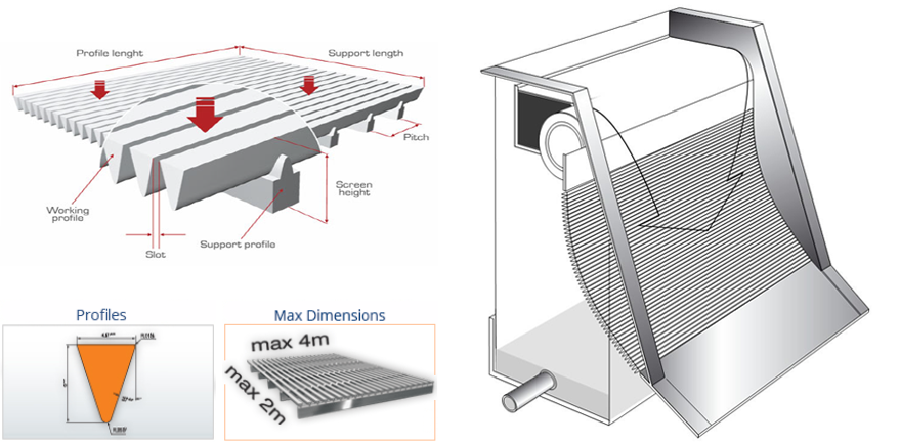

Welded Wedge Wire

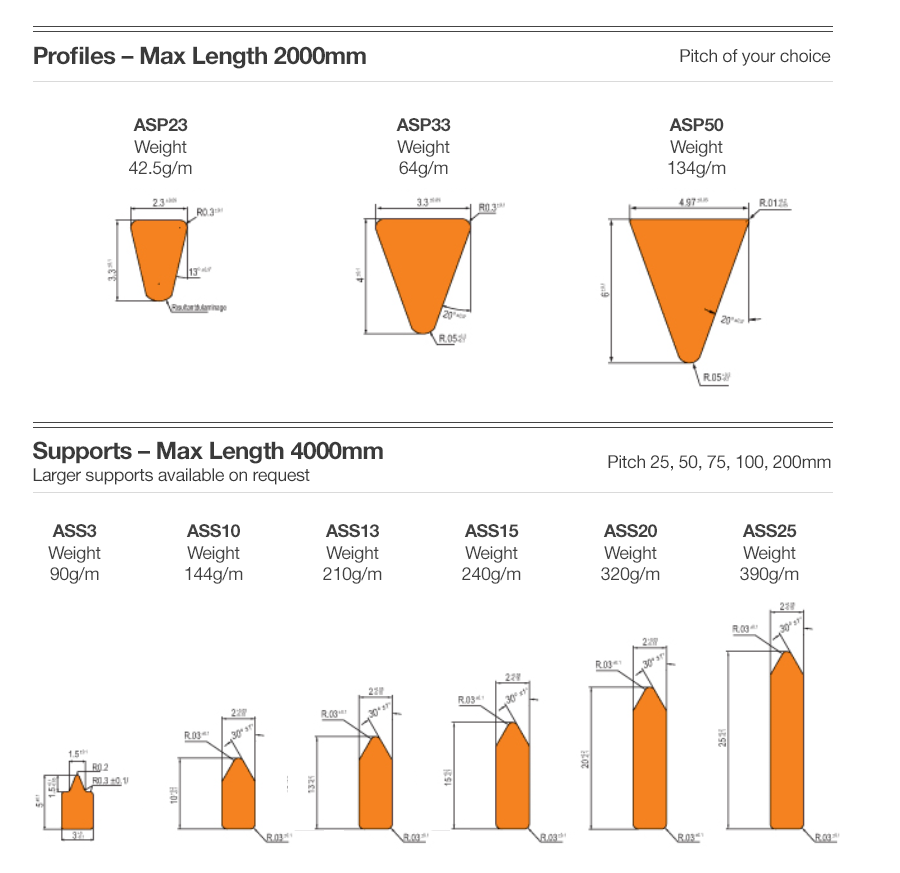

Welded wedge wire screens consist of sequentially arranged wedge wires which are rigidly connected to the cross support bars by means of resistant welding. This results in consistent screen openings or slots in-between the profiles. These slots can be adapted in their width according to application.

| Material | SS304 / SS316L |

| Finish | Plain / Satin / Grit 120, 220, 320, 400 |

| Profile Widths | 2.3mm / 3.3mm / 4.97mm |

| Slot Width | Customer Choice |

| Support Height (2 & 3mm Thick) | 5 / 10 / 13 / 15 / 20 / 25mm |

| Support Pitch | 20 / 50 / 75 / 100 / 200mm |

| Options | Frames / Channels / Lockdowns |

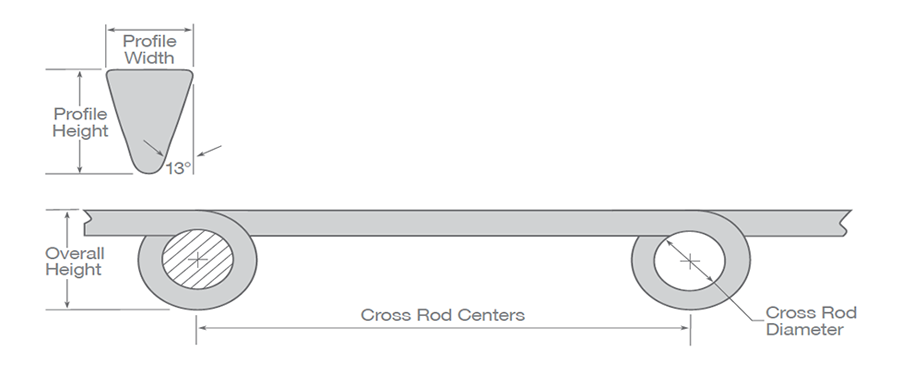

Looped Wedge Wire Screens

Looped wedge wire screens are pressed from round wire to the required profile building distance loops in the lower profile area. This enables the embedding of round cross bars through which the profiles are positioned and connected. This process of wedge wire screen construction achieves a maximum slot accuracy, as no heat development occurs during manufacture.