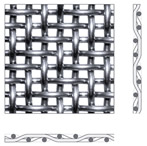

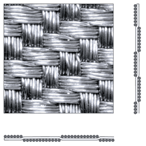

Plain Weave

Plain weave is produced by the alternately passing of the weft wires over and under the warp wires. This is the best known type of weave. It grants highly accurate mesh sizes.

Wire Mesh Products

Plain weave is produced by the alternately passing of the weft wires over and under the warp wires. This is the best known type of weave. It grants highly accurate mesh sizes.

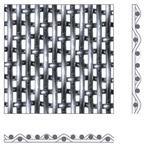

For the twilled weave, every third wire is tied in. This kind of weave is used when small mesh sizes meet wires with a larger diameter. Twilled weave is used for filtration and sieving purposes.

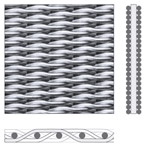

The warp wires of the plain dutch weave are thicker than the weft wires. The weft wires are weaved together as close as possible. The so-called "zero-mesh" or "closed mesh" is the result. The advantages are very uniform apertures and an efficient flow-through-rate

The weft wires are thicker than the warp wires. In contrast to a conventional dutch weave, the larger quantity of wires occurs in the warp. This kind of weave is often referred to as "reversed dutch weave". The advantages of this kind of mesh are high strength and a good flow through capacity.

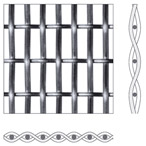

The most common mesh ratio is 1:3 / 3:1. To increase the stability, thw warp and the weft wires can have different diameters. This mesh is for example used for vibrating sieving screens.

A special kind of twilled weave - every fifth wire alternates over and under.

The up side and the under side of the fabric have a different structure - one side is smoother than the other and can easily be cleaned of filter cake for instance.

During weaving, the weft wires are forced together. In contrast to a plain dutch weave, this kind of mesh has a double number of weft wires. The advantages are a smooth surface for an easy removal of filter cakes and the suitability for ultra-fine filtration.

Multiplex weave is produced weaving wire bundles in wapr and weft direction. The thereby resulting large number of aprtures makes this kind of weave perfect for fine filtration.